The development status of China's machinery manufacturing industry

The machinery manufacturing industry is the most important part of the manufacturing industry. It is an industry that creates and provides mechanical products for users, including the entire process of mechanical product development, design, manufacturing, circulation, and after-sales service. In the entire manufacturing industry, the machinery manufacturing industry occupies a particularly important position. Because the machinery manufacturing industry is the equipment department of the national economy, it supplies and equips the various sectors of the national economy with various machinery and equipment, and keeps it developing. The development speed of the national economy depends to a large extent on the technological level and development speed of the machinery manufacturing industry.

Machinery manufacturing is a traditional industry. It has been developed for many years and has accumulated rich theoretical and practical experience. my country's machinery manufacturing industry started late, and there are problems such as weak foundations and technical blockades from other countries. However, after the founding of New China, my country established its own independent and complete machinery manufacturing industry, including light industry and heavy industry, and achieved world-renowned achievements. At present, China's machinery industry has formed an industrial system with more than 40,000 enterprises, more than 3 million machine tools, and more than 9 million employees. China is now a major manufacturing country, and the scale of China's manufacturing industry has reached the fourth largest in the world, second only to the United States, Japan and Germany. However, compared with industrialized countries, there is still a big gap. Mainly manifested in the low product quality and technical level, few products with independent intellectual property rights, backward manufacturing technology and process, unreasonable structure, backward technological innovation ability, and certain aspects of advanced manufacturing technology and production management. gap. But on the whole, China's machinery manufacturing industry has made undeniable achievements and made great contributions to economic and social development. Of course, it has also encountered many problems in the development process. Therefore, it is necessary to discuss the current situation of China's machinery manufacturing industry in order to have a clear understanding. The following aspects are important components of the machinery manufacturing industry. Through the analysis and comparison of these aspects, we can basically understand the current situation of my country's machinery manufacturing industry.

(1) Basic equipment. In the machinery manufacturing industry, machine tools, cutting tools, fixtures, testing instruments and other equipment largely determine the level of processing. However, many key parts and components cannot be manufactured in our own country and are completely dependent on imports, which limits the development of my country's machinery manufacturing industry to a large extent. However, looking at the world, we can see. The United States has integrated circuits and spacecraft, Germany has automobiles, and Japan’s machinery manufacturing. They all enjoy monopoly advanced technological advantages in these fields, forming unique, special and high-quality products, occupying the commanding heights of the world market, and possessing advanced manufacturing. Equipment is the guarantee of their success. On the other hand, my country's manufacturing technology and process equipment are very backward, and they have not mastered the world's advanced technology. Most of the products are produced with imported technology, and the high-tech content is not high. At present, most enterprises in my country still adopt relatively backward manufacturing technology and technical equipment for production. The penetration rate of high-quality, efficient and low-consumption technology is less than 10%, CNC machine tools and precision equipment are less than 5%, and mid-range CNC machine tools equipped with domestic CNC systems. No more than 25%, more than 90% of good CNC machine tools rely on imports; the technology of large-scale complete sets of equipment is seriously behind, and most large-scale instruments and equipment rely on imports. Mid-range products and many key components, foreign products account for more than 60% of my country's market, and so on. It can be seen that my country's machinery manufacturing equipment is still relatively backward, and there is still a certain gap with developed countries.

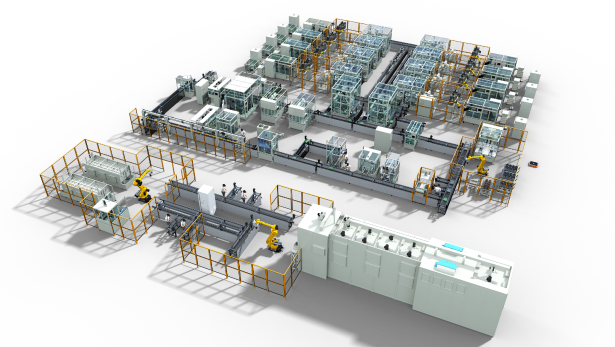

(2) Manufacturing process. With the development of science and technology, especially the rapid development of electronic technology and information technology, more and more high-tech applications are used in the machinery manufacturing industry. Especially in recent years, Made in China has become a familiar term for us, but at the same time, Made in China has almost become synonymous with inferior products. It can be seen from this that the quality of our products needs to be improved, which depends largely on Our manufacturing process. Industrial developed countries widely adopt new processing methods such as high-precision processing, fine processing, micro-processing, micro-machinery and micro/nano technology, laser processing technology, electromagnetic processing technology, superplastic processing technology, and composite processing technology. However, our country's penetration rate is not high, it is still under development and mastery, and traditional processing methods are still the main body, which restricts the improvement of our technological level. (3) Automation technology. With the development of high and new technology such as computer technology, the degree of automation technology in the machinery manufacturing industry has been further improved. Industrially developed countries generally adopt CNC machine tools, processing and flexible manufacturing cells (FMC), flexible manufacturing systems (FMS), and computer integrated manufacturing systems (CIMS) to achieve flexible automation, intelligence, and integration. my country is still in the stage of stand-alone automation and rigid automation, and flexible manufacturing units and systems are only used in a few enterprises. Moreover, our country's research in this area is still in its infancy, and its development is not yet mature.

(4) Production management. Industrial developed countries widely adopt computer management, attach importance to the renewal and development of organization and management system and production mode, and introduce new management ideas such as just-in-time production (JIT), agile manufacturing (AM), lean production (LP), concurrent engineering (CE), etc. And technology. Only a few large enterprises in my country have partially adopted computer-aided management, and most small enterprises are still in the stage of experience management. And it is precisely because of the small scale of our country's enterprises that most enterprises have failed to establish a modern scientific management system, the organization system is not perfect, the quality of personnel is low, and the management level is low. In most enterprises, there are problems such as emphasizing production technology and despising management technology; emphasizing hardware construction and despising software construction; emphasizing informatization and despising integrated management and so on. The level of professional management of enterprises is low, and the ability to develop international markets is weak. Most enterprises in our country have extensive management and low level of professional management. At this stage, the level of specialization of the machinery industry is only 15%-30%, while the level of specialization of American, Western European countries, and Japanese companies has reached 75%-95%.

(5) Core technology. Especially since the reform and opening up, more and more foreign companies have invested in China. my country has introduced a lot of foreign advanced equipment but has not mastered the core technology. Industry insiders believe that there is a huge technological "black hole" in my country's machinery industry, the most prominent manifestation is the high degree of dependence on foreign technology. The high degree of dependence on foreign technology has caused the development of my country's machinery manufacturing industry to be constrained by others. my country's dependence on foreign technology is as high as 50%, while the United States and Japan are about 5%, and the ratio in generally developed countries is also below 30%. In addition, my country's key technology self-sufficiency rate is low. Of the equipment investment that accounts for about 40% of fixed asset investment, more than 60% must be met by imports, and key high-tech equipment basically depends on imports. It is worth noting that the dependence on foreign technology in many important fields, especially in the field of national defense, will pose a severe challenge to national security. As a window of the National High-tech Industrial Development Zone, 57% of the technology comes from abroad. The industry generally believes that the formation of technological black holes is closely related to the state's attention and investment. In the past two decades, the country has neglected to develop the machinery industry, and there have been deviations in policies and funds. The most typical example is state-owned enterprises. State-owned enterprises have basically not implemented property rights incentives for innovative talents, and the property rights incentive system is an important guarantee for innovation and product research and development. On the one hand, the intellectual property rights of innovation achievements have not been effectively protected; on the other hand, the contributions of innovators have not been confirmed by property rights. The technologies and products developed by enterprises are either taken away by the state free of charge or copied by other enterprises free of charge. Take my country's automobile manufacturing industry as an example. my country's automobile manufacturing industry has been developing for many years, but very few people use the "heart" of their own design until now, which makes many people in the automobile industry feel sad. However, there are already several auto manufacturing companies that have begun to pay attention to designing their own engines. Chery is one of them. It has successfully developed ACTECO engines so that Chinese cars have begun to make technical money.

Enterprises not only lack core technologies, but also have weak innovation capabilities, and weak innovation capabilities have led us to follow others behind, making it difficult to master core technologies. my country's high-tech industry is developing rapidly, but there are not many products with independent intellectual property rights. Most of the export of high-tech products is completed by foreign-funded enterprises. Enterprises with independent intellectual property rights account for only three ten thousandths of the total number of enterprises. It is difficult for enterprises to master core technologies, and the problem of focusing on importing, ignoring digestion and absorption and re-innovating has not been effectively solved. In 2004, the expenditure for technology introduction of industrial enterprises above designated size was 39.7 billion yuan, and the expenditure for digestion and absorption was only 6.1 billion yuan, which is far lower At the level of Japan and South Korea. In today's world, the manufacturing industry is shifting to developing countries such as my country. China has become a global manufacturing country, attracting the attention of the world. However, due to the lack of core technologies and brands with independent intellectual property rights, many areas of the manufacturing industry still remain at the low end of the division of labor in the international value chain.

(6) The country's macro policies. The proportion of science and technology investment in GDP is still very low, and insufficient investment and waste and inefficiency coexist. Historically, my country’s investment in science and technology accounted for 2.32% of GDP in 1960, and then declined year by year, to 0.69% in 1998, and rebounded after 2000, to 1.23% in 2004, while innovative developed countries and newly industrialized countries This proportion is generally above 2%.

As a general competitive industry, the machinery industry is directly affected by the structure of production input. The competition among enterprises is actually the competition of scientific and technological strength and innovation ability, and the scientific and technological strength and technological innovation ability depend to a large extent on the investment in scientific research and development. In order to maintain the market competitiveness of the machinery industry, developed countries have increased their investment in science and technology. Some large companies' technology development expenses account for 4%-8%, or even more than 10%, of their sales. This high investment has further expanded its already advanced technological advantages and transformed the company from a situation of perfect competition to "monopolistic competition", occupying a strategic advantage position in many key areas. The per capita research and development funds of machinery industry companies in Japan, the United States, Germany, and France are respectively 215,400 US dollars/year, 157,600 US dollars/year, 199,000 US dollars/year, and 259,400 US dollars/year, which are dozens of times that of Chinese enterprises. From this, it can be seen that my country's funding investment is still lacking, which largely limits the development of my country's machinery manufacturing industry.

(7) Independent innovation and talent training.

The technological innovation ability of enterprises is poor, and the product development cycle is long. In our country, small and medium enterprises and large enterprises are still taking the road of low-cost industrial control automation. my country's automobile industry basically does not have its own brand on cars. In the machine tool manufacturing industry, most of precision machine tools and CNC machine tools rely on imports, which are basically uncompetitive in international bidding. According to reports: 30% of the leading products of China’s machinery industry reached the international level in the 1990s, 40% reached the international level in the 1980s, and 30% reached the international level in the 1960s and 1970s; large and medium-sized enterprises produce The average life cycle of more than 2,000 leading products of the United States is 10.5 years, which is 3.5 times the average life cycle of American machinery industry products; the contribution rate of new products in the American manufacturing industry has reached about 52% of GDP (1995), and China is only 5.9% (1997); the specialization level of machinery industry enterprises in the United States, Western Europe, and Japan is 75%-95%, while that of China is only 15%-30%; China has more than 80% of enterprises producing Insufficient or severely insufficient.

Talent is the core of independent innovation, but our country does not have top-notch innovative talents. This is fully reflected in the serious shortage of high-level talents and the lack of motivation for technological innovation. Although the overall scale of talents in my country is nearly 60 million, there is a shortage of high-level talents, and there are very few strategic scientists who can rank among the international frontiers and participate in international competition. Among the 158 international first-level scientific organizations and the 1566 major second-level organizations included, the number of scientists participating in the leadership of my country only accounts for 2.26% of the total, of which only one is chaired by the first-level scientific organization, and the second-level organization Only 1% are chairpersons.

The number of invention patents is small, and the quality of domestic scientific research papers is relatively low. my country's current invention patents account for only 2% of the world's total, and most of the tripartite patents (the number of patents granted by the United States, Europe and Japan) are owned by more than 20 innovative countries recognized worldwide. Although the number of international scientific and technological papers in my country has leapt to the fifth place in the world, it still lacks major original innovations leading to the development of disciplines. From 1993 to 2003, the number of SCI (Science Citation Index) papers cited by authors in various disciplines in the world was counted. There are no Chinese scholars in the top 20, and only 2 in the top 100.

(8) The development of high-precision technology is relatively weak. High-precision technology will play a major role in the future international competition. For example: underwater operation equipment used for the development of marine resources; ultra-precision processing equipment used for high-precision equipment manufacturing, key integrated circuit manufacturing equipment for IT and other industries; micro-electromechanical systems (MEMS) and high-tech integrated Humanoid robots, etc.; due to foreign technical blockades, only general equipment and general technology can be introduced. It is difficult to introduce core technologies and can only be mastered by own research, and development can only be achieved by self-reliance.

In summary, there is still a certain gap between my country's machinery industry and the world, especially in terms of technology and management. These aspects are related to whether our country can catch up in the future development of machinery manufacturing. Therefore, as mechanical students, we should be ambitious and integrate our own development into the development of my country's machinery industry, recognizing the above gap. I believe that through the joint efforts of each of us, my country's machinery manufacturing industry can be made bigger and stronger.